Wrought Forged

Wrought and Forged Products

Aluminum forging offers a number of outstanding advantages over other manufacturing processes such as sand casting. Properties of the aluminum alloy represent only the beginning of end-user benefits. The forging process adds superior mechanical and physical properties created by heat and pressure.

Among the key advantages:

1. Low specific weight which is why fuel costs resulting from a lower weight of vehicles, vessels, planes, etc. can be reduced.

2. Resistance to atmospheric agents (because aluminium products are not subject to corrosion which reduces restoration costs).

3. Excellent electrical conductivity (aluminium and its alloys constitute the only useful material for the transmission of high-voltage power).

4. Specific mechanical properties facilitate relatively good shaping and reshaping thereof.

5. Safe material in terms of health.

6. Can be recycled and subsequently reused.

7. Long lifespan.

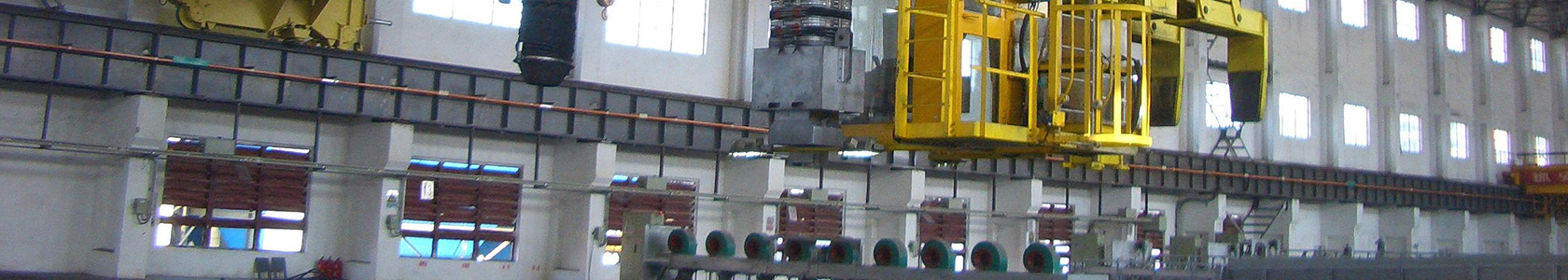

Chalco is capable to produce 2000、5000、6000 and 7000 series aluminum forging products with high technical added value, the products cover aviation, vessel, petroleum and petrochemical, rails and transportation and energy industries etc.

Application:

1. Aviation area: forging such like landing gear, supporting beam of landing gear, frame of cabin door, wing forgings, mount forgings for engine, case shell of engine, turbine engine disc etc. Capable to manufacturer more than 90% of the forgings on airplane.

2. Ship area: various forging for ships such like crankshaft, rudder stock, cylinder cover, universal joint pin, gear, transmission shaft and connecting rod etc.

3. Power energy: super alloy turbine disc, engine rotor, generator retaining ring, impeller, shaft coupling and other powder energy equipment forgings.

4. Rails and transportation: axle box body of locomotive, piston of locomotive etc. Aluminum axle box body and piston for high speed train.

5. Petroleum and petrochemical: shell ring,flange, long neck flange, tube plate, valve, blind plate, adapter tube of forging, boss and so on forgings.

6. Others: forgings used on large mechanical equipment, products cover broad areas and meet requirements of different customers.

Aluminum forging offers a number of outstanding advantages over other manufacturing processes such as sand casting. Properties of the aluminum alloy represent only the beginning of end-user benefits. The forging process adds superior mechanical and physical properties created by heat and pressure.

Among the key advantages:

1. Low specific weight which is why fuel costs resulting from a lower weight of vehicles, vessels, planes, etc. can be reduced.

2. Resistance to atmospheric agents (because aluminium products are not subject to corrosion which reduces restoration costs).

3. Excellent electrical conductivity (aluminium and its alloys constitute the only useful material for the transmission of high-voltage power).

4. Specific mechanical properties facilitate relatively good shaping and reshaping thereof.

5. Safe material in terms of health.

6. Can be recycled and subsequently reused.

7. Long lifespan.

Chalco is capable to produce 2000、5000、6000 and 7000 series aluminum forging products with high technical added value, the products cover aviation, vessel, petroleum and petrochemical, rails and transportation and energy industries etc.

|

|

|

|

Application:

1. Aviation area: forging such like landing gear, supporting beam of landing gear, frame of cabin door, wing forgings, mount forgings for engine, case shell of engine, turbine engine disc etc. Capable to manufacturer more than 90% of the forgings on airplane.

2. Ship area: various forging for ships such like crankshaft, rudder stock, cylinder cover, universal joint pin, gear, transmission shaft and connecting rod etc.

3. Power energy: super alloy turbine disc, engine rotor, generator retaining ring, impeller, shaft coupling and other powder energy equipment forgings.

4. Rails and transportation: axle box body of locomotive, piston of locomotive etc. Aluminum axle box body and piston for high speed train.

5. Petroleum and petrochemical: shell ring,flange, long neck flange, tube plate, valve, blind plate, adapter tube of forging, boss and so on forgings.

6. Others: forgings used on large mechanical equipment, products cover broad areas and meet requirements of different customers.

|

|

| Production capacity | ||||||

| Forging | Types | Max Weight | Max Measurement | Alloy | Temper | Standard |

| Open Die Forge | cube | ≤5T | Length≤7000mm; width≤2000mm; height≤500mm |

2219 2618 2B50 2A50 2A70 2A80 2D70 2A14 2014 2A11 2A12 2024 3A21 4032 5A90 5210 5A02 5A03 5083 5A05 5A06 6A02 6061 6A02 7A04 7B04 7A09 7075 7050 7A19 7A10 |

O F H112 T3 T4 T5 T6 T62 T652 T73 T7452 T852 Etc. |

GBn223 YS/T479 ASTM B247 |

| disc | ≤5T | diameter≤2500mm | ||||

| ring | ≤5T |

Outer diameter of quenching parts≤2500mm; outer diameter of non-quenching parts≤4000mm; height≤500mm |

||||

| cylinder | ≤5T |

Out diameter 200--800mm; Length≤2000mm; outer diameter 801-2000mm; length≤1500mm |

||||

| axle | ≤8T | length≤7000mm, diameter≤800mm | ||||

| Closed Die Forge | PVA≤3.0(Diameter ≤1950mm) | |||||

|

Complicated closed die forge parts |

PVA≤1.5㎡\ (Diameter≤1400mm) |

|||||