Alu. Brazing Sheet

Aluminum Brazing Sheet

For Brazed Automobile Heat ExchangersCladding an aluminum-silicon alloy with a brazing sheet provides an aluminum alloy that has the thin walls necessary for use in automobile heat exchangers, as well as such desirable characteristics as high strength, corrosion resistance and formability. We have developed and are refining a variety of products of this sort.

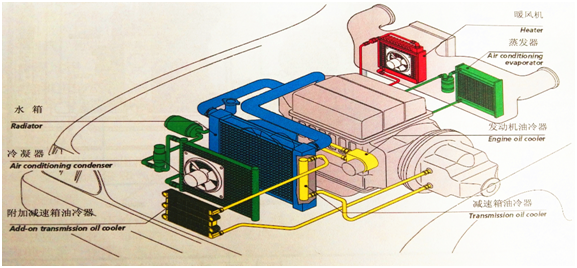

Heat Exchanger On Vehicle Application

A. Air conditioning evaporator B. Condenser

C. Heater D. Water cooler

E. Motor oil cooler F. Inter cooler

Chalco Aluminium Brazing Sheet and Strips

Specification and Data Sheet

| Dimensions | ||

| Strips | Sheets | |

| Thickness | 0.051mm--3.0mm | 0.4mm--6.35mm |

| Width | 6mm--1600mm | 500--1600mm |

| Length | Max. 10000mm | |

| Edge quality | Trimmed | Trimmed and slit; sawn |

|

Inside diameter |

305mm, 405mm, 505mm Paper core, Aluminium core, without core. |

|

| Outside diameter | Max. 1600mm without connect point | |

| Cladding | |

| Cladding | One side; Both sides |

| Cladding rate |

5%, 7.5%, 10%, 13%, 15% (other clad percentages available upon request) |

| Cladding tolerance |

Cladding thickness of 1.5%--<4%: +/-0.6 Cladding thickness of 4.0--6.0%: +/-1.0 Cladding thickness of 6.0--<=12.0%: +/-1.5 Cladding thickness of 12.0--20.0%: +/-2.0 |

| Surface | |

| Quality | Mill finish; for thickness 0.3--3.5mm, chemically degreased |

| Marking | Ink marking |

A. Tolerance according to EN and ASTM.

B. Higher thickness on request.

C. Special dimensions , tolerances, and alloys on request.

| Chalco Aluminium Chemical composition | |||||||||||

| CHALCO ALUMINIUM CLAD ALLOYS | Others | ||||||||||

| Alloy 合金 | Si | Fe | Cu | Mn | Mg | Cr | Zn | Ti | each | total | |

| Clad alloys for VCA-brazing according to EN573-3 | |||||||||||

| 4004 |

Min. max. |

9.0 10.5 |

- 0.8 |

- 0.25 |

- 0.10 |

1.0 2.0 |

- - |

- 0.20 |

- - |

- 0.05 |

- 0.15 |

|

4104 (Containing0.02% -0.20% Bi) |

Min. max. |

9.0 10.5 |

- 0.8 |

- 0.25 |

- 0.10 |

1.0 2.0 |

- - |

- 0.20 |

- - |

- 0.05 |

- 0.15 |

| Clay alloys for CAB-brazing according to EN573-3 | |||||||||||

| 4343 |

Min. max. |

6.8 8.2 |

- 0.8 |

- 0.25 |

- 0.10 |

- - |

- - |

- 0.20 |

- - |

- 0.05 |

- 0.15 |

| 4045 |

Min. max. |

9.0 11.0 |

- 0.8 |

- 0.30 |

- 0.05 |

- 0.05 |

- - |

- 0.10 |

- 0.20 |

- 0.05 |

- 0.15 |

| 4047A |

Min. max. |

11.0 13.0 |

- 0.6 |

- 0.30 |

- 0.15 |

- 0.10 |

- - |

- 0.20 |

- 0.15 |

- 0.05 |

- 0.15 |

| Zn-containing clad alloys for CAB-brazing | |||||||||||

| 4343.ZN |

Min. max. |

6.8 8.2 |

- 0.8 |

- 0.25 |

- 0.10 |

- - |

- - |

0.8 1.2 |

- - |

- 0.05 |

- 0.15 |

| 4045.ZN |

Min. max. |

9.0 11.0 |

- 0.8 |

- 0.30 |

- 0.05 |

- 0.05 |

- - |

0.8 1.2 |

- 0.20 |

- 0.05 |

- 0.15 |

| Clad alloys for corrosion protection according to EN573-3 | |||||||||||

| 1050A |

Min. max. |

- 0.25 |

- 0.40 |

- 0.05 |

- 0.05 |

- 0.05 |

- - |

- 0.07 |

- 0.05 |

- 0.03 |

- - |

| 7072 |

Min. Max. |

- 0.7(Si+Fe) |

- 0.10 |

- 0.10 |

- 0.10 |

- - |

0.8 1.3 |

- - |

- 0.05 |

- 0.15 |

|

| All data in Wt.-%; Customer specific alloy composition on request. | |||||||||||

| 3××× alloys according to EN573-3 and ASTM | |||||||||||

| 3003 |

Min. max. |

- 0.6 |

- 0.7 |

0.05 0.25 |

1.0 1.5 |

- - |

- - |

- 0.10 |

- - |

- 0.05 |

- 0.15 |

| 3004 |

Min. max. |

- 0.30 |

- 0.70 |

- 0.25 |

1.0 1.5 |

0.8 1.3 |

- - |

= 0.25 |

- - |

- 0.05 |

- 0.15 |

| 3005 |

Min. max. |

- 0.6 |

- 0.70 |

- 0.30 |

1.0 1.5 |

0.20 0.6 |

- 0.10 |

- 0.25 |

- 0.10 |

- 0.05 |

- 0.15 |

|

3103Containing max.0.10%(Zr+Ti) |

Min. Max. |

- 0.50 |

- 0.70 |

- 0.10 |

0.9 1.5 |

- 0.30 |

- 0.10 |

- 0.20 |

- - |

- 0.05 |

- 0.15 |

| 3105 |

Min. Max. |

- 0.6 |

- 0.7 |

- 0.30 |

0.30 0.80 |

0.20 0.80 |

- 0.20 |

- 0.40 |

- 0.10 |

- 0.05 |

- 0.15 |

| 5×××-non-heat-treatable alloys according to EN573-3 and ASTM | |||||||||||

| 5049 |

Min. max. |

- 0.40 |

- 0.50 |

- 0.10 |

0.50 1.10 |

1.60 2.50 |

- 0.30 |

- 0.20 |

- 0.10 |

- 0.05 |

- 0.15 |

| 5052 |

Min. max. |

- 0.25 |

- 0.40 |

- 0.10 |

- 0.10 |

2.2 2.8 |

0.15 0.35 |

- 0.10 |

- - |

- 0.05 |

- 0.15 |

| 5083 |

Min. max. |

- 0.40 |

- 0.40 |

- 0.10 |

0.40 1.0 |

4.0 4.9 |

0.05 0.25 |

- 0.25 |

- 0.15 |

- 0.05 |

- 0.15 |

| 6×××-non-heat-treatable alloys according to EN573-3 and ASTM | |||||||||||

| 6063 |

Min. max. |

0.20 0.60 |

- 0.35 |

- 0.10 |

- 0.10 |

0.45 0.90 |

- 0.10 |

- 0.10 |

- - |

- 0.05 |

- 0.15 |

| 6951 |

Min max. |

0.20 0.50 |

- 0.08 |

0.15 0.40 |

- 0.10 |

0.40 0.8 |

- - |

- 0.20 |

- - |

- 0.05 |

- 0.15 |

| 7×××-non-heat-treatable alloys according to EN573-3 and ASTM | |||||||||||

|

7020 Containing 0.08%- 0.25% (Zr+Ti) and 0.08%--0.20% Zr |

Min. max. |

- 0.35 |

- 0.40 |

- 0.20 |

0.05 0.50 |

1.0 1.4 |

0.10 0.35 |

4.0 5.0 |

- - |

- 0.05 |

- 0.15 |

|

Chalco Aluminium Physical Property Data of Strip Material |

||||||||||||||||

|

Alloy |

Temper |

Thickness (mm) |

Tolerance (mm) |

Clad Ratio (%) |

Tensile Strength (MPa) |

Yield Strength (MPa) |

Elongation (%) Min |

Application |

||||||||

| 3003 | H14 | 0.08~0.12 | ±0.005 | None | 150~200 | ≥120 | 1 |

Evaporator fin and plate |

||||||||

| 3003 | H26 | 0.3~0.35 | ±0.015 | None | 190~220 | ≥160 | 8 |

Glass mounting bracket material |

||||||||

| 3003 | H14 | 0.06~0.1 | ±0.005 | None | 150~200 | ≥120 | 1 |

Radiator fin and plate |

||||||||

|

4343/3003/ 4343 |

H14 | 0.06~0.1 | ±0.005 | 8~12 | 150~200 | ≥120 | 1 | |||||||||

|

4343/3003/ 4343 |

H14 | 0.08~0.12 | ±0.005 | 8~12 | 150~200 | ≥120 | 1 |

Parallel condenser fin |

||||||||

|

4343/3003/ 4343 |

H14 | 0.1~0.12 | ±0.005 | 8~12 | 150~120 | ≥120 | 1 |

Charge air cooler material |

||||||||

|

4045/3003/ 4045 |

H14 | 0.1~0.12 | ±0.005 | 8~12 | 150~200 | ≥120 | 1 | |||||||||

| 1060 | O | 0.35~0.4 | ±0.02 | None | 55~95 | ≥15 | 25 |

Air cooling fin material for tubes |

||||||||

| 1100 | O | 0.35~0.4 | ±0.02 | None | 75~105 | ≥25 | 25 | |||||||||

| 3003 | O | 0.2~0.3 | ±0.01 | None | 100~150 | ≥45 | 15 |

Aluminium for heating element |

||||||||

| 3003 | H16 | 0.5~0.7 | ±0.02 | None | 150~210 | ≥120 | 1 | |||||||||

| 4047 | H18 | 0.05~0.1 | ±0.005 | None | ≥200 | ≥170 | 0.5 | |||||||||

| 4047 | O | 0.4~0.5 | ±0.02 | None | 80~140 | ≥35 | 12 | Welding wire | ||||||||

| 7072 | H19 | 0.12~0.15 | ±0.005 | None | 145~172 | ≥15 | 0.5 | Fin stock | ||||||||

| 4A13 | H18 | 0.05~0.1 | ±0.005 | None | ≥190 | ≥16 | 0.5 |

Aluminium for heating element |

||||||||

| 4104 | H18 | 0.05~0.1 | ±0.005 | None | ≥220 | ≥190 | 0.5 | |||||||||

|

3003 (inner fin) |

O | 0.2~0.3 | ||||||||||||||