In recent years, more and more attention by the manufacturers of anti-counterfeiting bottle cap, as a part of the packaging, the security function and production form is toward diversification, the development of high-grade, niuduanshi, open type, multiple anti-counterfeiting bottle cap is widely used in factory. Although the function of the anti fake bottle cap is constantly changing, there are two main types of materials used in it: aluminum and two kinds of plastics. In the world, the cover of wine packaging bottle covers the aluminum closure, the outer star is simple, the production is fine, it brings the elegant visual feeling to the consumer. Compared with plastic cap, aluminum closureis not only superior in performance, but also can be mechanized, large scale, low cost, no pollution, and can be recycled.

And the aluminum closureis simple, but it is fine. The advanced printing technology makes the color and lustre consistent, the pattern is exquisite, and gives people exquisite and elegant feeling. The bottle cap style of foreign wine is mostly used in traditional mode, which has little change. For example, the bottle cap of Scotch whisky, the pure black with golden character gives people the same enjoyment of simplicity and elegance, but also plays its marked role. Industry people think, in the wine bottle cap, aluminum anti-theft cover will still be the mainstream.

The aluminum plastic anti-counterfeiting cover has complex structure and has the function of preventing backwash. Its surface treatment methods are varied, strong sense of three-dimensional and unique appearance and appearance, but its defects can't be ignored. Because the glass bottle adopts the thermoforming process, the size error of the bottle mouth is large, and it is difficult to achieve high sealing. Packaging experts point out that due to the existence of strong static electricity, plastic caps are easy to adsorb the ash in the air, and the debris produced by ultrasonic welding is difficult to eliminate. The problem of wine detritus on liquor pollution is not yet completely solved. In addition, a few plastic bottle cap manufacturers to reduce costs, adulteration in the raw materials, health conditions are worrying. As the lid of a bottle is connected to a glass bottle, it is not easy to recover, and environmental experts believe that its pollution to the natural environment is obvious. In addition, the cost and cost of plastic bottle cap is about twice as much as that of aluminum closure.

In comparison, the aluminum burglar cap can serve the defects on the plastic cap of the plastic bottle. Thealuminum closure has the advantages of simple structure, strong adaptability and good sealing effect. It can not only print colorful patterns, but also achieve mass production and low cost. If the special advanced printing method is adopted, the effect of the aluminum closure is good.

The aluminum closure is made from high quality special aluminum alloy material. It is mainly used for encapsulation of liquor, beverage (including gas, gas free) and medicine and health care products, and can meet the special requirements of high temperature cooking and sterilizing lamp.

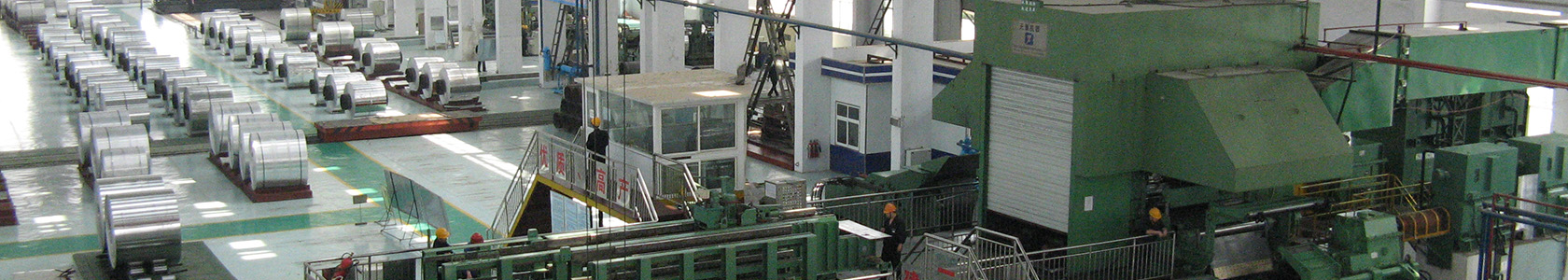

aluminum closure is mostly processed in a highly automated production line, so the requirements for material strength, elongation and size deviation are very strict, otherwise it will produce cracks or creases in processing. In order to ensure printing bottle forming, surface smooth, no requirement of cap material roll marks, scratches and stains, Aluminum Alloy state generally used 8011 H14, 3105H16, general specification of material thickness of 0.20---0.23mm, width of 449mm---796mm. aluminum cap material production can be used for hot rolling slab or billet for continuous casting and rolling, then cold rolling.

aluminum closure and plastic bottle cap have more advantages compared with them. They can not only be mechanized, large-scale, but also have large cost, low pollution, and can be recycled. Therefore, in the future, the aluminum closure will remain the mainstream in the future.

And the aluminum closureis simple, but it is fine. The advanced printing technology makes the color and lustre consistent, the pattern is exquisite, and gives people exquisite and elegant feeling. The bottle cap style of foreign wine is mostly used in traditional mode, which has little change. For example, the bottle cap of Scotch whisky, the pure black with golden character gives people the same enjoyment of simplicity and elegance, but also plays its marked role. Industry people think, in the wine bottle cap, aluminum anti-theft cover will still be the mainstream.

The aluminum plastic anti-counterfeiting cover has complex structure and has the function of preventing backwash. Its surface treatment methods are varied, strong sense of three-dimensional and unique appearance and appearance, but its defects can't be ignored. Because the glass bottle adopts the thermoforming process, the size error of the bottle mouth is large, and it is difficult to achieve high sealing. Packaging experts point out that due to the existence of strong static electricity, plastic caps are easy to adsorb the ash in the air, and the debris produced by ultrasonic welding is difficult to eliminate. The problem of wine detritus on liquor pollution is not yet completely solved. In addition, a few plastic bottle cap manufacturers to reduce costs, adulteration in the raw materials, health conditions are worrying. As the lid of a bottle is connected to a glass bottle, it is not easy to recover, and environmental experts believe that its pollution to the natural environment is obvious. In addition, the cost and cost of plastic bottle cap is about twice as much as that of aluminum closure.

In comparison, the aluminum burglar cap can serve the defects on the plastic cap of the plastic bottle. Thealuminum closure has the advantages of simple structure, strong adaptability and good sealing effect. It can not only print colorful patterns, but also achieve mass production and low cost. If the special advanced printing method is adopted, the effect of the aluminum closure is good.

The aluminum closure is made from high quality special aluminum alloy material. It is mainly used for encapsulation of liquor, beverage (including gas, gas free) and medicine and health care products, and can meet the special requirements of high temperature cooking and sterilizing lamp.

aluminum closure is mostly processed in a highly automated production line, so the requirements for material strength, elongation and size deviation are very strict, otherwise it will produce cracks or creases in processing. In order to ensure printing bottle forming, surface smooth, no requirement of cap material roll marks, scratches and stains, Aluminum Alloy state generally used 8011 H14, 3105H16, general specification of material thickness of 0.20---0.23mm, width of 449mm---796mm. aluminum cap material production can be used for hot rolling slab or billet for continuous casting and rolling, then cold rolling.

aluminum closure and plastic bottle cap have more advantages compared with them. They can not only be mechanized, large-scale, but also have large cost, low pollution, and can be recycled. Therefore, in the future, the aluminum closure will remain the mainstream in the future.