Domestic aluminum spraying fluorine carbon coating is widely used 230 ℃ high temperature baking can be fused into the membrane of the PVDF fluorocarbon coatings, not only waste the more electricity, and PVDF fluorocarbon coatings are unable to get to meet customer requirements of various colors, its low glossiness, and can not get make painting repair, application scope is limited. Thermosetting solution of fluorocarbon polyester (FEVE) coating solution by introducing the melamine resin or enclosed isocyanate resin as cross-linking agent, under the condition of heating curing film by chemical reaction, thus it can be made into Chinese baking (180 ℃) curing one-component coating, for the user to save a large amount of electrical energy;Because of FEVE fluorocarbon resin polymer strictly arranged alternately structure, make its weather-ability and traditional PVDF as well, because the FEVE fluorocarbon resin is transparent, so it can be obtained by light to highlight within the scope of the coating, coating color is more bright-coloured, the coating is painting, can reduce costs, the choice of solvent, convenient and flexible construction performance is also improved.

FEVE fluorocarbon resin as film forming matter, through curing system, solvent system and the selection of additives, such as the Chinese baking coating performance is prepared, change of coating has excellent mechanical properties, resistance to salt fog resistance and weather-ability, each index has reached the requirement of HG/T 3793-2005.

FEVE fluorocarbon paint has a high level of protection and color retention, which is the most prominent weather-resistant anti-corrosive coating

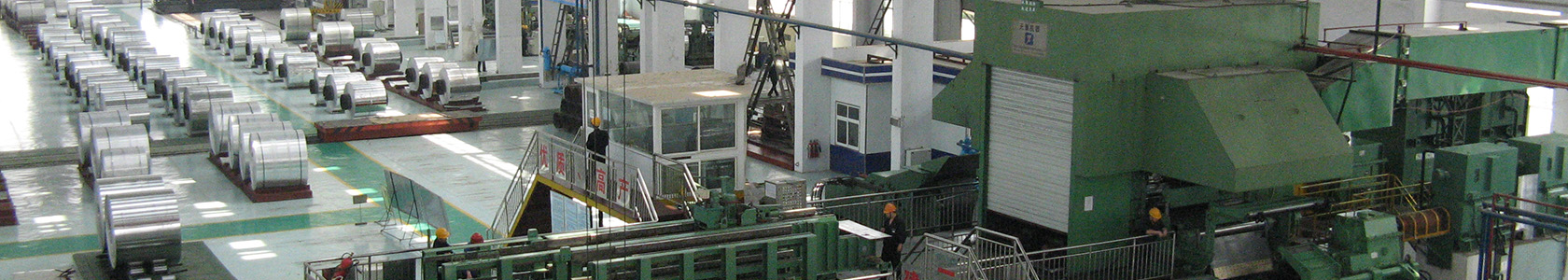

FEVE coated aluminum sheet has good corrosion resistance, UV resistance, is sports venues, high-speed rail station, power plants, steel mills, large public buildings and high salt fog, high altitude coating preferred products.Under normal environment, the anti-corrosion and anti-fading properties of FEVE coated aluminum sheet can reach 20 to 25 years, and the film integrity can be over 50 years.