8011 coated aluminum tagger foil are popular packaging materials at home and abroad. Compared with traditional plastic bottle cap or tinplate bottle cap, it has good sealing performance, high pressure resistance, corrosion resistance, beauty and environmental protection, and is favored by consumers.

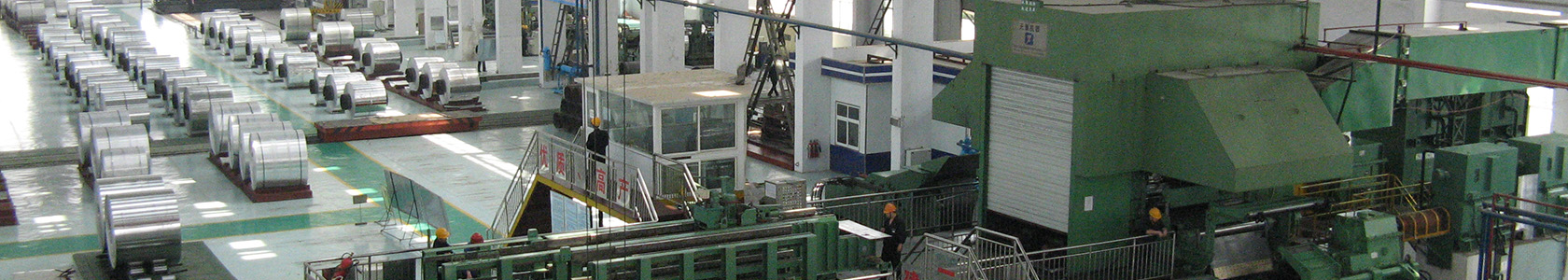

In addition to its good formability and low anisotropy, its manufacturing materials also require multiple color printing curing, which has a certain baking intensity. At present, the alloy used to produce coated aluminum tagger foil is generally 8011 alloy. Because of the needs of users in the process of baking, cover paint, polishing and five heating processes, the highest temperature can reach 230 ℃, every working time is 12 minutes, a total of 1 hours, which requires the coating formula to build mechanical properties of coated aluminum tagger foil with high stability. Henan Signi aluminum Co.,Ltd has made great efforts to study the production of coated milk powder and its aluminum foil has basically realized the characteristics of high productivity, high yield, strong rolling performance and high rupture strength.

Normal size:

8011 O, thickness above 50 mircron, both sides varnished, in coil size.